Processing, Application and Sizes of Galvanized Chicken Wire

|

|

|

|

Galvanised steel mesh chicken wire is divided into two types: electro galv. chicken wire and hot dipped galv. chicken wire. The core wire is mild steel wire or carbon steel wire. The zinc rate of the electro wire is 15g-30g/㎡and the zinc rate of hot dipped wire is 30g-100g/㎡.Hexagonal opening also offers good ventilation.

Application: Galvanized carbon steel chicken mesh is used for protecting poultry and livestocks. Sometimes it can be used as a fence of the park. The galvanized chicken wire is also used in machinery protection, fences for road, railway, etc. As to some heavy galvanized chicken wire ,it can be made into gabions to hold stones and sand against the flood to protect the bank, hillside, bridge and other related civil engineering.

Process: galvanized after weave and galvanized before weave.

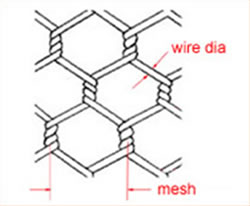

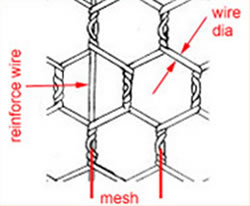

Twist type: normal twist or reverse twist.

Galvanized chicken wire sizes:

Mesh size: 13mm, 25mm, 40mm, 50mm, 75mm, and 100mm.

Wire thickness: 0.7mm - 1.6mm.

Usually mesh size/wire: 13mm/0.7mm, 16mm/0.7mm, 20mm/0.7mm, 25mm/0.8mm, 40mm/0.9mm, 50mm/1.0mm, 75mm/1.2mm, 75mm/1.4mm, 100mm/1.6mm.

Width: 0.5m, 0.75m, 1.0m, 1.5m, 1.8m, 2.0m

Length: 10m, 25m, 50m, or cut it to your desired length packed in rolls.

PRODUCT LISTS

- Chicken Wire Products:

- Green Coated Chicken Wire

- Welded Chicken Wire Mesh Cage Panels

- Chicken Wire Netting

- Chicken Wire Specifications

- Chicken Wire Mesh

- PVC Coated Chicken Wire Mesh

- Chicken Wire Fence

- Poultry Netting

- Rabbit Netting

- Chicken Cage

- Rabbit Cage

- Poultry Cage

- Weaving Patterns of Chicken Wire

- Chicken Wire Applications

- Chicken Wire Floral Netting

- Stainless Steel Chicken Wire

- Mild Steel Galvanised Wire Netting

- Garden Wire Netting

- Poultry Wire Fence

- Deer Netting

- Stucco Netting

- Plastic Chicken Netting

- Copper Chicken Wire

- Materials

- Machines:

Contact Us

Add: Development Area, Dezhou, China